How to produce a die casting zinc alloy soft enamel challenge coin in aohui gifts?

As a professional manufacturer for all kinds of custom challenge coin,mint coin,mint commemoratives etc.,here is our standard steps to produce a custom challenge coin,mint coin,commemoratives in high quality and speed turnaround time.

The very first step is to send us your idea or logo or any images you have in any format such as jpg format or png format or ai format or PSD format or CDR format etc.

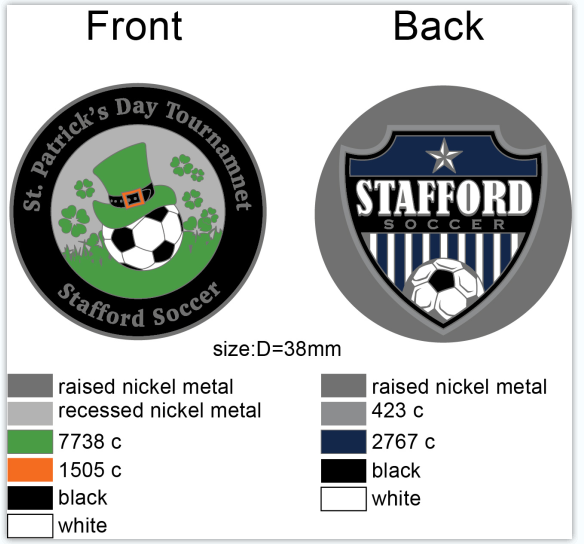

Then our professional designer will send you our production artwork with enamel colors coded, platings, size, edge etc. for approval.

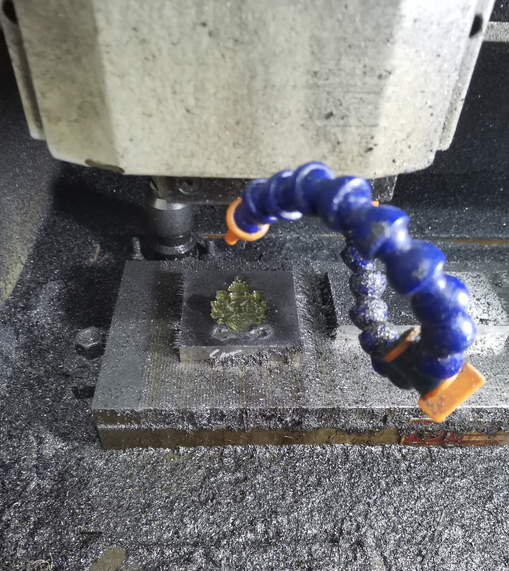

After artwork is approved,it will go into mold engraving steps.

Our experienced mold technicians are very good at designing high relief 3D details to make the figures or buildings as closest to the real figures as possible,the most vivid type.

The 4th step would be checking mold and polishing mold after mold is ready,this step would guarantee all details on physical products are perfect as artwork and the metal part would be as most smoothing and shiny as possible.

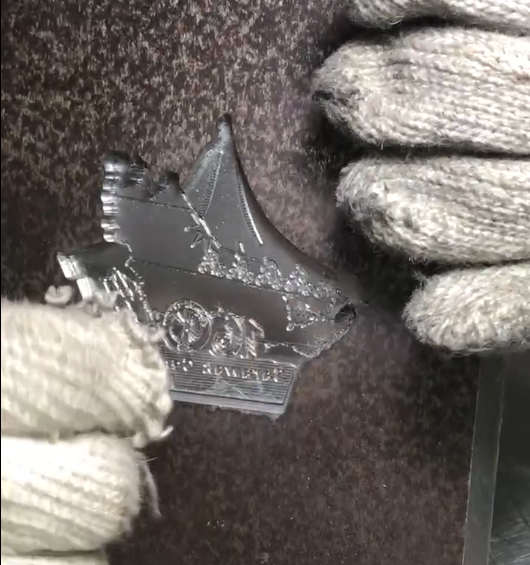

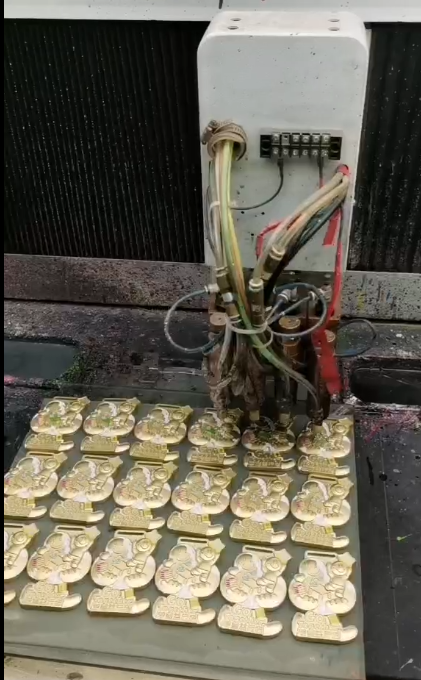

The 5th step would be either die casting the coins,the coins to shape the coin per artwork after mold is done.

Then we will check out the unplated coins to make sure things are good and correct.

The 6th step will be polishing and remove blurs etc after coins casting is ready. Polishing would make the finished coin with shiny smooth metal and edge is smooth as well.This step is very important as well because the polishing need to ensure details of high relief is reserved well however surface of metal is smooth enough.

The 7th step is to do plating after polished casting is ready.

During this step,the coin can be different kinds of plating finishing such as most common finishing would be gold or nickel or copper or black nickel or bronze or antique silver or antique gold or antique bronze or antique copper or dual plating gold+nickel,shiny+antique finishing or matte finishing etc. There are abundant plating options with us to achieve an idea challenge coin for you.

Once plating is done,the next step will be soft enamel, in another words,to make the challenge coin colored.In the past 10 years,this process is done by hand however with technology developed now,we have automatic enamel machine to do it which could make the process more efficient and accurate as well. However labor still can do very minor area or complicated designs as hand is more flexible.After few hours baking,enamel will be dry then the challenge coin is official done with the very last step.

The final step would be to do 100% inspections of the challenge coins to make sure our customer got all goods in good conditions.Then to pack the coin and protect it from damage during transportations to our oversea customers.

We are putting efforts at every step to ensure our customer get good products from us.

Post time: Feb-18-2022